The midterm deliverable of WP5 (D5.3) has been completed. The purpose of this deliverable is to report the preliminary results of the conceptual process design (CPD) and techno-economic evaluation (TEE). These results highlight the integration potential and identify the optimization hotspots for further developments.

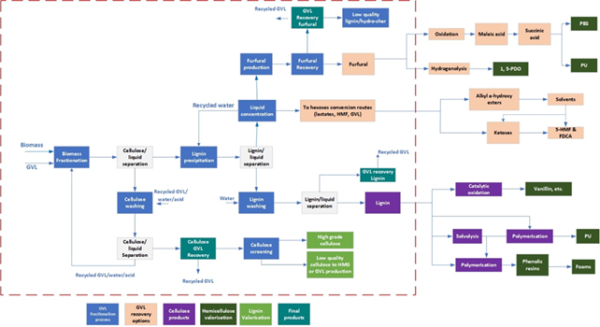

The core of FRACTION biorefinery concept is the GVL biomass fractionation process into cellulose, lignin, furfural and/or hemicelluloses. This boundary is indicated by the dashed line in the figure below.

This deliverable has focused mainly on the biomass fractionation section. The Fraction project identified 10 various biomass feedstocks to be investigated in order to select the appropriate feedstocks of interest for Fraction’s biorefinery concept and strategy. These feedstocks include 5 types of pure biomasses and 5 mixtures of those biomasses. The types of biomasses that have been selected are Eucalyptus (EU), White Birch (WB), Pinus Sylvestris (PS), Sugarcane bagasse (SCB) and Old corrugated cardboard (OCC). These feedstocks were tested experimentally to investigate the main products quality and yields. Based on the results, the base-case process concept was modelled for 7 of the identified feedstocks. 4 biomass feedstocks ( EU, WB, SCB and PS) were further selected for more detailed process design and optimization .

CPD and TEE studies have been conducted on four processes where each focuses on fractionation of one of the 4 selected biomasses. The studies involved investigating various process concepts, performing first-order mass and energy balances, conceptual process design, short-cut equipment design and techno-economic assessment. PROSYN® (PDC’s expert system) has been used for investigating the process concepts and for performing the techno-economic assessment. Aspen Plus has been used to simulate and validate the investigated process concepts. In order to represent the properties of the system to be investigated and to allow accurate simulation results a physical property model has been developed.

A comparison between the base-case process and the current process was performed to highlight the achieved improvements. The comparison showed that the current process realized 35% of CAPEX savings and 83% of manufacturing expenses (OPEX) saving. Detailed sensitivity analysis on the process economics was performed to identify the key hotspots of optimization for further development. It has been found that the steam consumption/price is the key driver for the reduction of the manufacturing expenses. Full heat integration and optimization of the lignin precipitation step are identified as the major contributors to the steam consumption. Increasing plant capacity and onsite production of GVL are highlighted as important parameters for further optimization.

For more information: WP5 leader, Eng.D Mohamed Mahmoud, Mahmoud@process-design-center.com, PDC

More project results here.